Certainty through precision

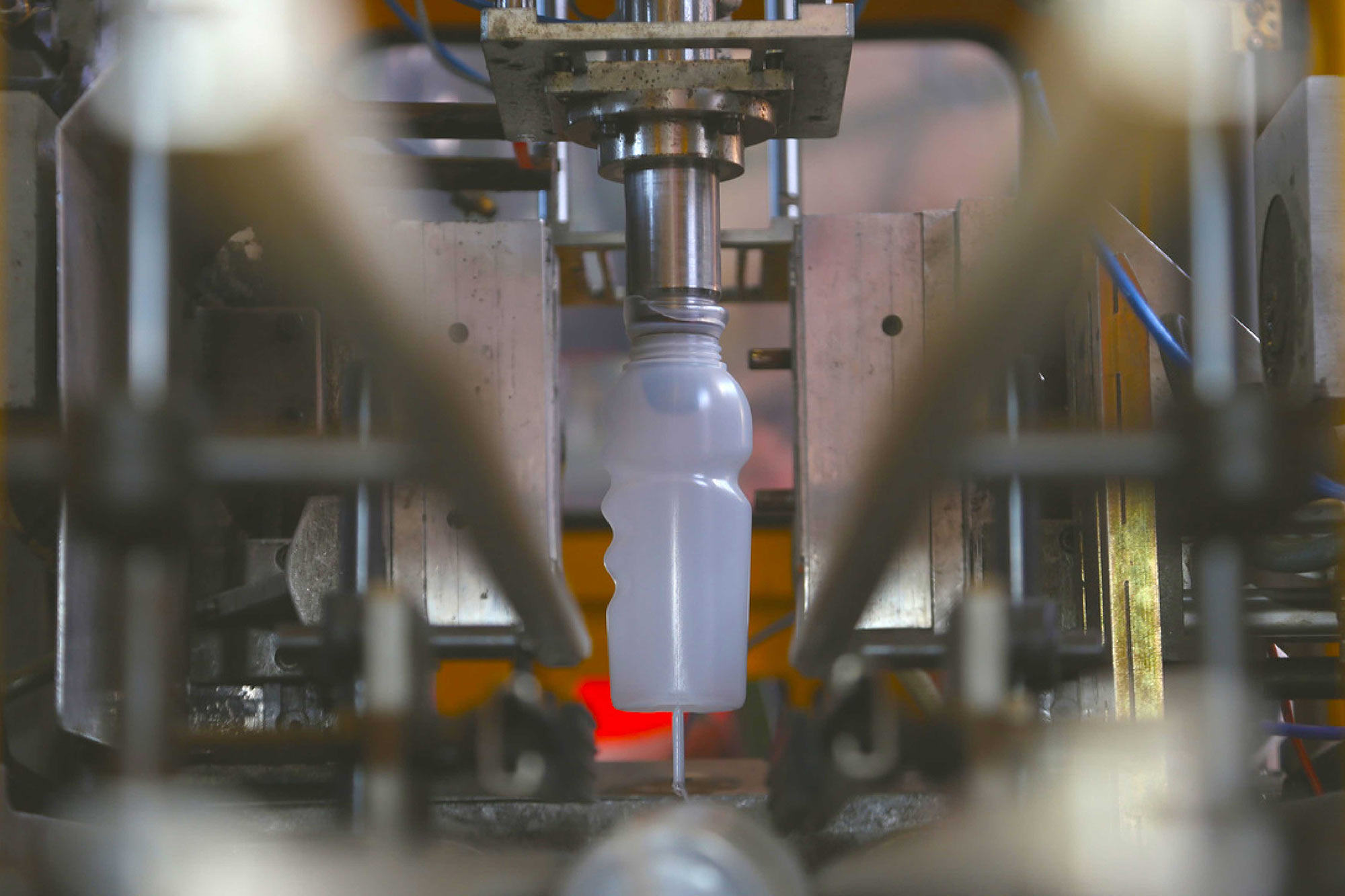

Leveraging our decades of expertise in plastic injection and blow moulding, and coupled with our robotic technology in our state-of-the-art manufacturing facility, we have the capabilities onsite to provide prototype development and volume production with agile lead times.

We offer a sophisticated manufacturing service combining component production, robotic and manual secondary process, with clean room assembly and printing to manufacture bespoke products and components across medical and industrial use.

We can also advise and act on existing product refinements to reduce production, component, and assembly cost, as well as reduce the volume of plastic used and identify different and potentially more environmentally friendly alternatives.

We provide

Product design

Tooling

On site assembly

Speed & agility

Small runs

Bespoke printing

High volume production up to 850 tonnes

Prototype development

Recycled/recyclable materials & components advice

Despatch

Technical blow moulding

We have the ability to produce high quality, blow mouldings in a wide variety of sizes ranging from 5 ml to 80 litres in an assortment of materials and colours to meet most requirements. In addition, our extensive expertise and experience provides the assurance of a seamless transition from design to manufacture.

Technical parts can be produced with a variety of features

- Threaded necks and internal threads

- Bends, convolutes and other complex forms

- Varying material thickness and high tolerance

- Integrally moulded handles

- Plastic or metal inserts

- Riveted-on extrusions

- Undercuts and flanges to facilitate post assembly operations

- Additives including flame retardants

- Colour matching

- Materials include HDPE, LDPE, MDPE, PP, ABS, Post-Consumer Recycled HD, glass filled nylon and types of TPR

Injection moulding

Our in-house capabilities enable us to produce injection moulding parts ranging from 22 to 850 tonnes. The robotic technology we have in place provides us with the efficiencies needed to ensure our production times are the best they can be, in turn reducing the lead time to market. World leading companies and organisations choose Inpress to create custom-made products for them.

We are able to create custom-made products using any of the following materials:

- Polyethylene

- ABS

- Polystyrene

- HDPE and LDPE

- Nylon filled and unfilled

- UV resistant and antistatic additives

To discuss turning your product designs into reality,

please call us on +44 1903 724128